Top Ten Uses for Additive Manufacturing in Defense

Add bookmark

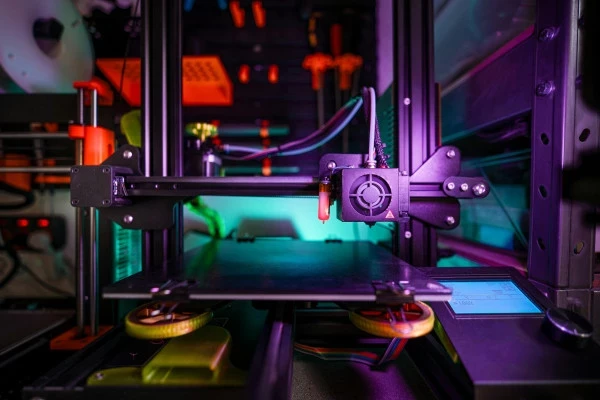

The rise of additive manufacturing, or 3D printing, has had an impact on every industry, and the defense space is no exception. A decade ago, IDGA shared the first iteration of our top ten uses of additive manufacturing in defense. Those uses included tasks like printing food or treating injured soldiers. In 2025, some things on that list have stayed true, while others are no longer relevant uses of additive manufacturing in defense.

Before Advanced Manufacturing for Defense kicks off this June 24-25 at the Hilton Los Angeles in Culver City, California, IDGA wanted to refine our list of the top ten uses of additive manufacturing in defense.

1. Enhancing the Manufacturing Process

When looking at additive manufacturing’s impact on the defense industry from a wider lens, it’s clear that technologies such as 3D printing have reimagined the way defense agencies and companies can manufacture weapons, parts, and much more.

Some of the benefits of shifting towards additive manufacturing as opposed to traditional processes include:

- Cost reduction

- Design enhancements

- Reduced time to reach the end-user

- Increase technical and commercial competitiveness

2. Parts Replacements

It’s no secret that the time to manufacture a part with older tech, such as CNC Machining, can be far more time-consuming than using Metal 3D Printing. With 3D printing, defense agencies have the opportunity to standardize parts manufacturing internally and thus be able to replace parts for tools needed in air, sea, and land. This can be incredibly impactful because, in high-stakes environments, which are common in the military, the difference in the time it takes to replace a part can impact lives.

3. Supply Chain Resilience

Additive manufacturing can reduce dependence on traditional supply chains by allowing the local production of spare parts and components, enhancing operational resilience. Dr. Mohsen Seifi, the Vice President of Global Manufacturing Programs at ASTM International, says the defense industry is beginning to see the positive impact additive manufacturing is having on the supply chain.

“A trend we see is the ability to produce parts on demand and closer to the point of need that enhances the resiliency of the defense supply chain against any sort of disruptions and reduce dependency on global supply chains,” said Dr. Seifi.

4. Unmanned Systems

The global defense industry is in a race to produce and deploy unmanned systems, whether that’s unmanned aerial vehicles (UAVs), ground robots, or other autonomous systems. In fact, in the defense space, the global military drone market was valued at USD 12.55 billion in 2022 and is projected to grow from USD 14.14 billion in 2023 to USD 35.60 billion by 2030, exhibiting a CAGR of 14.10% during the forecast period. Using additive manufacturing to produce components of unmanned systems gives organizations a leg up by being able to produce these parts on a quicker time frame and for less.

5. Military Equipment

Additive manufacturing has revolutionized how manufacturers can work with materials from composites to plastics, metals, and much more. Because of the variety of materials that 3D printers and other additive manufacturing tools can work with, there are many different applications for using additive manufacturing to produce military equipment. Some examples of military equipment that can be produced with additive manufacturing include small arms, uniforms, body armor, field equipment, vessels, aircrafts, vehicles, and artillery.

6. Satellite and Space Technology

One of the biggest obstacles for both manned space missions and satellite manufacturing is the expense. The rule of thumb for NASA is that every unit mass of payload launched requires the support of an additional 99 units of mass, with “support” encompassing everything from fuel to oxygen to food and medicine for the astronauts. However, if manned space missions have a 3D printer onboard, NASA would not need as many replacement parts available but rather provide the raw materials that can be crafted into any number of things when needed.

7. Ammunition Production

While munitions could certainly fall under the military equipment category, it gets its own section because of the impactful applications we have already seen of 3D printers producing ammunition. In the summer of 2023, Ukraine was facing a legitimate munitions shortage, and as a result, the Ukrainian artillery was forced to carefully select targets and prioritize military equipment over groups of infantry. While waiting for munitions reinforcements, the Ukrainian military used 3D printers to create small, inexpensive munitions that could be dropped from drones onto targets, thus allowing the Ukrainian military to expand its targets.

8. Underwater Equipment

Additive manufacturing allows for the creation of intricate shapes crucial for optimizing underwater equipment performance without the limitations of traditional manufacturing methods. This flexibility is especially beneficial for components requiring complex geometries, such as sensor housings and hydrodynamic structures. Similar to space technology, by keeping a 3d printer on board underwater vessels, crews won’t be required to keep as many spare parts on-hand.

9. Building Shelters

In 2018, the U.S. military became the first country to 3D print a concrete military barracks, and the feat only took two days to complete. Automated Construction of Expeditionary Structures, or ACES, is a U.S. Army program is exploring the use of 3D printers to create semi-permanent structures. The program has found that 3D printing reduces the amount of building materials that have to be shipped by half and reduces construction manpower requirements by 62 % compared to expedient plywood construction.

In February 2025, the U.S. Army made 3-D printed barracks operational when G-9 (Installations), 1st Armored Division, and Fort Bliss Garrison leaders cut ribbons on three 3-D printed buildings at Fort Bliss in Texas. Each of the new buildings is capable of housing up to 56 soldiers.

10. Medical Devices

The U.S. military is a significant proponent and investor in regenerative medicine and 3-D bio-printing, and we are already beginning to see the benefits of these efforts. For example, the VA has gone from owning two 3D printers to having over thirty in the span of a decade, and these printers are already improving veterans quality of life and saved money because of the high success rate of custom-printed parts and reduced hospital visits. All these innovations mean soldiers can benefit from on-site 3D printing of medical devices and prosthetics, improving medical care in VA hospitals or remote locations.

Learn More About Advanced Manufacturing For Defense

Join us on June 24-25, 2025, at the Hilton Los Angeles Culver City for IDGA's Advanced Manufacturing for Defense Summit. In our 3rd iteration of the event, we will explore the cutting-edge realm of additive manufacturing, a sector set to surpass a staggering value of USD $76.16 billion by 2030.

Learn More